Ah, it’s been a while, Fatal Error #1. Have you missed me?

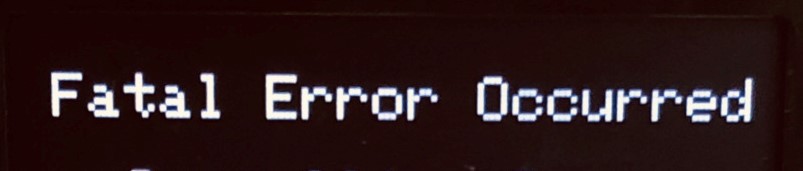

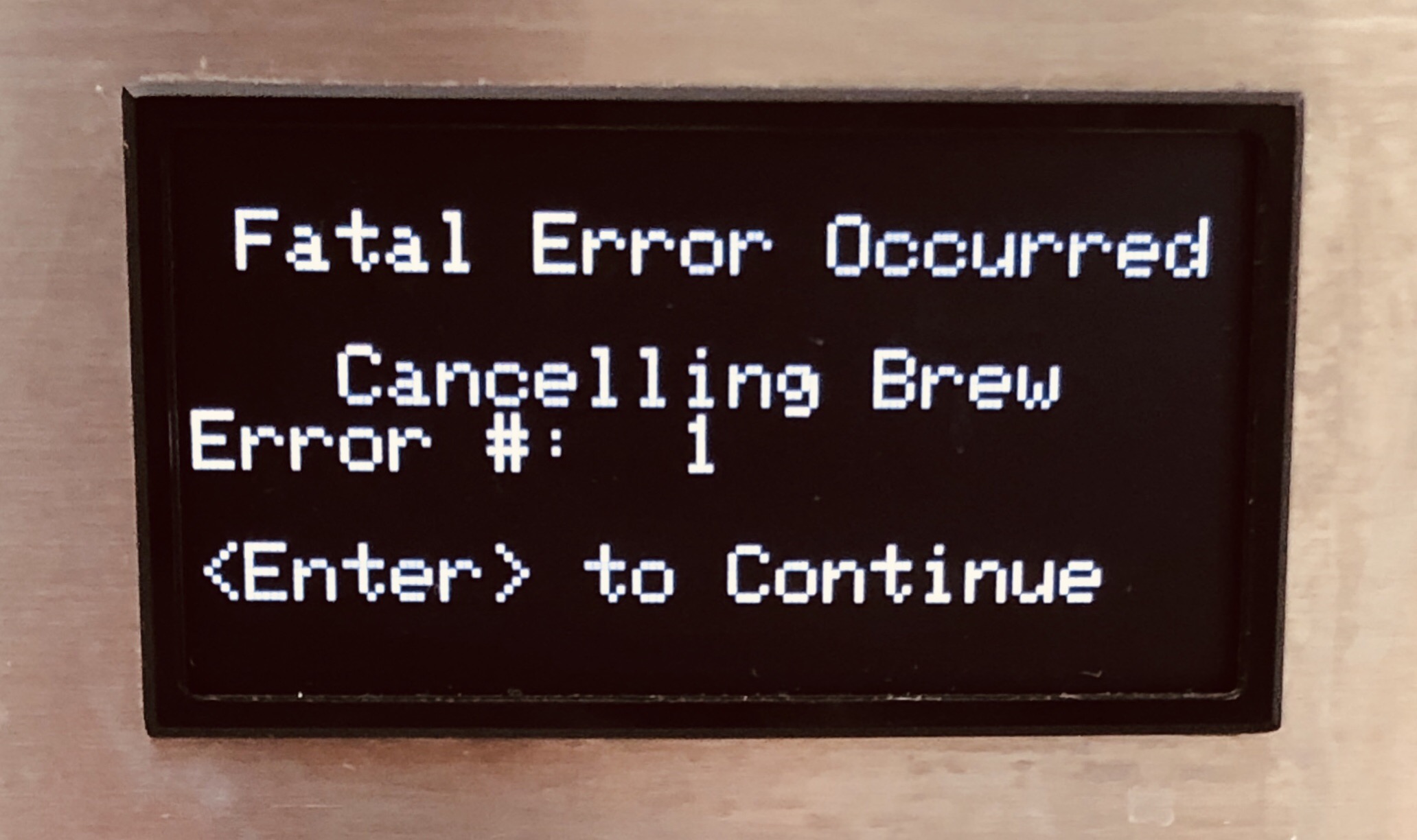

Yes, after several months gathering dust, I switch on the Zymatic to see whether the Picobew servers were still working. And they were. Wow. So I did a quick rinse and set out to make a brew. And I was met with my old chum: Fatal Error #1!

My post My Fatal Error #1 was buying a Zymatic is the top post on Google for Zymatic FE1, and every so often I’ll get a mail asking me how I fixed it. At the time Picobrew was still in operation, I was in contract with them about FE1, and they were actually reading my blog – I know this because the support person got pissed when I wrote something unfavourable about his attitude and I had to delete it to get further support! – so I was deliberately vague about the solution.

Doesn’t seem much point being vague now, eh?

Picobrew insists (insisted?) that FE1 is caused by gunk in the machine – eg in the heat exchanger – which causes a difference between the wort and heat loop temperature sensors. Anyone (previously) contacting them would be told to clean, clean, and clean some more. Now don’t get me wrong, cleaning is a good thing. But Picobrew never got past that. They never admit that this happens:

See that bubble. That’s an air bubble in the glycol which is being pumped through the heat exchanger. Looks small and innocent enough, doesn’t it? Well, with a bit of massaging to move air hidden in the “closed loop”, it becomes this:

And THAT is the cause of Fatal Error 1 in my case. Somehow over time this air bubble develops in the closed loop, and no amount of cleaning will help that. Switch the machine on and run a brew, and the machine with bork out after a few minutes due to heat sensor differences, shown clearly in the session graph:

I should point out that there could be other reasons for a FE1 – in fact anything that would cause a difference between in temperature between sensors. A blockage where the machine is sucking in air rather than water/wort, for example. Or massive amounts of gunk in the machine – hence Picobrew recommending cleaning. But there gets to a point where you’ve ruled out all the daft things and cleaned the machine more than you clean your teeth before going to the dentist, and you still have FE1 and a graph like the above.

If you get a Fatal Error 1 at the start of the brew, first check you haven’t made any silly mistakes – like connect the hoses the wrong way round. If all looks ok and you still get FE1 after restarting, check the session graphs to confirm the heat differences.

If it’s your first time encountering FE1 and – like myself – you have a brew loaded up, it is (usually) possible to get past the FE1 and get the brew going. Once the water temp hits around 80-100F, the machine is able to continue the brew to the end without hitting FE1 again. So if you hit FE1, run a cycle with the water going through the machine for a minute or two, then restart the brew. And keep doing that until the water gets hot enough and FE1 stops happening. You can help the process by removing the water from the keg, heating it on a stove, and putting it back in the keg before restarting, to get you into the 80-100F zone.

This is what the session graph looks like after the brew finally gets going. You can see the large difference between Heat 1 and Heat 2 at the beginning, and you can also see how it spikes up and down at that time. As the brew progresses, the difference between the heat sensors falls, but there is still a large gap between the wort temp and the heat sensors temp. Chances are if you look at your previous successful brew, it it was recent, you’ll see gaps between the heat 1 & 2 readings at the beginning, and a difference between the wort and temp sensors later on.

That solution mentioned above is temporary, to get the brew going. To fix properly, you’ll need to top up the glycol like so:

And then Bob’s your granma’s uncle. Working Zymatic again. This is what the graph looks like after top-up:

Massive difference, eh? See how much closer Heat 1 and Heat 2 are throughout the brew. See also how close the wort temp is. You do see some wort temp drops at the end of dough in and mash 1 – those co-incide with the wort draining and so are normal.

Below is a PDF outlining the glycol top-up process. Before you download it, please read this warning/disclaimer CAREFULLY.

- I am not the author of the guide and I am making it available as it was provided to me because it helped me and because many people have asked me how I fixed FE1 on my Zymatic. I take no responsibility for your usage of the guide.

- USE EXTREME CAUTION WHEN FOLLOWING THE PROCEDURE (OR DO NOT PERFORM IF YOU DON’T FEEL COMFORTABLE). USE THE PROCEDURE AT YOUR OWN RISK. DAMAGE TO YOUR ZYMATIC CAN OCCUR. THERE IS RISK OF ELECTRICAL SHOCK THAT COULD RESULT IN DEATH. THIS PROCEDURE IS FOR REFERENCE ONLY.

Seriously – the Zymatic pumps hot fluids through it and there are electrical everywhere. You need to be very careful. And if that wasn’t enough, some of the edges inside the Zymatic are razor sharp and I have cut myself dismantling the Zymatic. You follow the guide at your own risk.

If you want to get in touch with me, leave a comment. I do not publish comments but I do reply when I can.

You must be logged in to post a comment.